Additive manufacturing is here to stay – is your practice on board?

3D printing, also known as additive manufacturing, is that rare once-in-a-generation technological innovation that has the ability to transform global manufacturing industries and commerce in general as we know it.

To be honest, it kind of already is. In fact, according to the most recent Worldwide Semiannual 3D Printing Spending Guide from International Data Corporation (IDC), revenue in this amazing industry is projected to reach $28.9 billion by 2020.

Currently, the largest sectors cashing in on additive manufacturing are automotive design, rapid prototypes manufacturing, and aerospace and defense parts printing. However, many may be surprised to find that just two years from now, the dental industry is projected to be a substantial player.

In fact, one SmartTech report found that last year alone, dental 3D printing grew by over 35%. This same report predicted that the dental market would represent a $9.5 billion (USD) opportunity by 2027.

Research analyst Carla La Croce projects that not only is dental 3D printing “growing rapidly” but it also has the “prospect of reaching one of the highest market shares in the near future.”

If you’ve been interested in learning more about this amazing technological advancement and how it is impacting the dental industry both presently and in the future read on.

So what exactly is 3D printing?

3D printing, known as additive manufacturing, is a layer-by-layer process by which a computer creates a three-dimensional, physical object from a digital design.

For certain products it is a more cost-effective spin on the traditional subtractive manufacturing which entails the cutting/hollowing out of a block of substance (typically some form of metal or plastic) to create a three-dimensional, physical object, usually the result of a milling process. Of course subtraction manufacturing has been around for decades (Cerec) and is now represented even more widely in dentistry with many systems of digital impressioning combined with machined fabrication of porcelain crowns and bridges by means of 3D milling units. (Our practice uses the combination of either 3M’s True Def scanner or Itero’s scanner, with Glidewell’s upgraded TS150 milling unit. Admittedly, until the TS150 upgrade and availability of BruxZir NOW blocks, the performance of the Ts150 was not very good at all.)

The benefit of additive manufacturing (3D printing) is that it allows the production of shapes of much greater complexity while simultaneously utilizing less material than traditional manufacturing methods.

How is 3D printing used in dentistry?

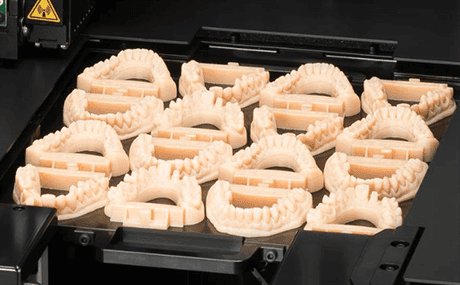

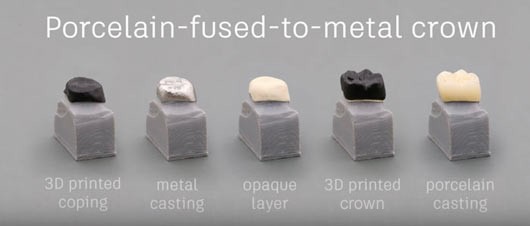

3D printing is used extensively in labs, including both resin and SLM printing (Selective Laser Melting). Selective Laser Melting is an additive manufacturing technique that can print metal parts in 3D, by means of a laser melting metallic powder in specific places. Additionally, a growing number of dental offices use resin printing in a number of different ways.

According to Nick Azzara, Chief Sales and Marketing Officer at BEGO, USA, resin printing offers “great options to many solutions inconvenient to mill” and gets the job done well regarding tooth fabrication in terms of both strength and aesthetics.

SLM 3D printing, on the other hand, is particularly great for producing “select components” such as copings and frameworks for single units and bridges, as well as surgical tools. The whole process, whether in the lab or in the dental office, is driven by intraoral 3D scanner imaging sending digital files to milling units, where precise fabrication of dental products occurs “without investing, casting, and some of the challenges that go with the lost-wax technique.”

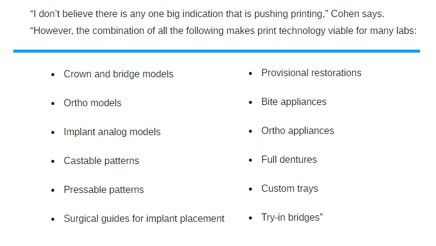

Crowns, surgical guides, orthodontic appliances – you name it , 3D printing can help create them in a more accurate, efficient, and cost-effective manner in many instances.

“Everything is still model-based,” says Jeff Youngerman, a representative for 3D printing giant Stratasys.

One notable manufacturer other than Stratasys is Form Labs, whose Form 2 SLA printer offers “intuitive, reliable stereolithography for the desktop.” The Form 2 starts at $3,350.00, and according to the manufacturer, “makes 3D printing affordable for dental businesses of all sizes.” Recently, at the Hinman dental meeting in Atlanta I noticed that Henry Schein was displaying a Form 2 in their booth. Apparently, there may be some sort of distribution agreement between these companies.

Source

The future of 3D printing in dentistry.

“The key will be printing the final restoration with clean and easy post-processing. That’s the end game for 3D printing in the dental industry,” says Chris Frye, the Digital Technology Solutions Sales Manager and Dental Channel Sales Manager with Whip Mix.

This game-changing opportunity could become a reality within as little as five years, pending the availability of improved substrates, according to one article by Modern Dental Network.

With the addition of new and improved materials and colors, one could easily begin to mirror both tooth “form and color mapping to build an identical 3D replacement.”

In future I suspect that most of us will have 3D printers in our labs that enable manufacturing a wide variety of resin appliances in a very fast and accurate manner. In our group practice one of our doctors, generally an early adopter of a lot of technology, purchased a $1000 Prusa Mk 2 3D printer. He assembled it himself and spent quite a bit of time learning how to print with it. Unfortunately, at top speed, it took about 4 to 5 hours to crank out even the most simple model or surgical guide. That, and his reports of surface irregularities, have him wanting us to purchase a Form 2.

Regardless, the end result is nothing but net decreased overhead, more efficient workspaces and improved patient experiences.

Conclusion

There are limitless potential benefits for creatively harnessing the power of additive manufacturing in dentistry. 3D printing already can reduce time and increase accuracy and efficiency for fabrication of models, splints, surgical guides, etc. I am certainly looking forward to seeing how the future unfolds for dental offices and labs alike.

Please feel free to share your comments on this article and your own experiences with 3D printing.

Best regards,

Pat

Sources:

https://pinshape.com/blog/3d-printing-dental-applications/

http://www.evansondds.com/how-3d-printing-is-revolutionizing-dentistry/ https://3dprinting.com/what-is-3d-printing/#Future of 3D Printing

http://www.dentalproductsreport.com/lab/article/what-future-holds-3d-printing

https://www.idc.com/getdoc.jsp?containerId=prUS42211417

http://www.dentalproductsreport.com/lab/article/3d-printing-made-dental-market-very-valuable-2017